Six Sigma is a structured approach to business management that concentrates on improving quality by reducing process variability and eliminating major failure mechanisms. Since it relies heavily on the collection and analysis of data, statistical programs such as Statgraphics are a vital component of all serious Six Sigma implementations. Lean Six Sigma adds important concepts from lean manufacturing, which concentrates on the elimination of unnecessary resource utilization.

When beginning a Six Sigma project, it is important to understand the problem to be addressed and the factors that most effect quality and cost. Statgraphics' Centurion XVII contains several procedures that are helpful in this area along with Six Sigma and Lean Six Sigma tools.

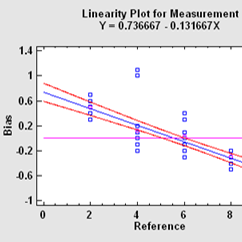

When implementing any statistical method that relies on data, it is important to be sure that the systems that collect that data are both accurate and precise. A set of procedures, often referred to as "Gage Studies", are widely used to assess the quality of measurement systems and are included in the Six Sigma Toolbox.

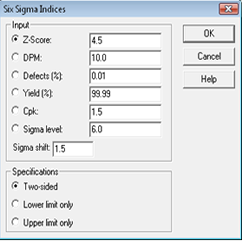

An important technique used to determine how well a process meets a set of specification limits is called a process capability analysis. A capability analysis is based on a sample of data taken from a process and usually produces: 1. An estimate of the DPMO (defects per million opportunities). 2. One or more capability indices. 3. An estimate of the Sigma Quality Level at which the process operates. The Statgraphics toolbox provides Six Sigma and Lean Six Sigma tools necessary for these results.

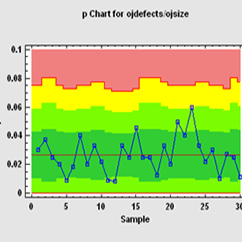

One of the most important actions that can help maintain the quality of any good or service is to collect relevant data consistently over time, plot it, and examine the plots carefully. All statistical process control charts plot data (or a statistic calculated from data) versus time, with control limits designed to alert the analyst to events beyond normal sampling variability as part of our Six Sigma and Lean Six Sigma tools.

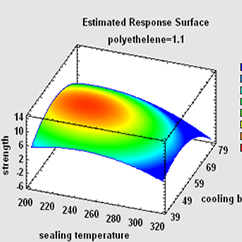

Statgraphics contains extensive capabilities and Lean Six Sigma tools for the creation and analysis of statistically designed experiments. The designs that can be created are divided into several types such as response surface designs which are intended to determine the optimal settings of the experimental factors. The designs involve at least 3 levels of the experimental factors: Box-Behnken designs, 3-level factorials, and Draper-Lin designs.

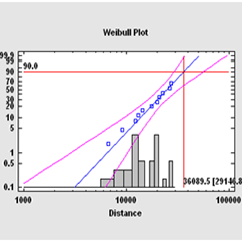

Determining the reliability of manufactured items often requires performing a life test and analyzing observed times to failure. Such data is frequently censored, in that some items being tested may not have failed when the test is ended. In addition, it may be necessary to accelerate failure times by changing the value of an influential variable such as temperature. For all of these reasons, special Six Sigma or Lean Six Sigma tools are needed to deal with this type of data.

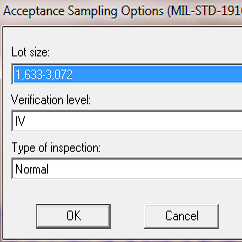

When lots containing a relatively large number of items require inspection, acceptance sampling plans can provide reasonable protection against shipping or receiving an unacceptable fraction of non-conforming items without inspecting 100% of the lot. The Acceptance Sampling procedures generate acceptance sampling plans by on either attributes or variables.

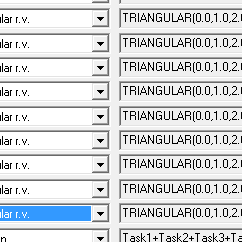

Monte Carlo simulation is used to estimate the distribution of variables when it is impossible or impractical to determine that distribution theoretically. It is used in many areas, including engineering, finance, and DFSS (Design for Six Sigma).

Download the Six Sigma Toolbox and Lean Six Sigma Tools Brochure.

Or learn more about the all new Statgraphics XVIII

© 2025 Statgraphics Technologies, Inc.

The Plains, Virginia

CONTACT US

Have you purchased Statgraphics Centurion or Sigma Express and need to download your copy?

CLICK HERE